Commitment to Quality

Westlake Plastics is certified to ISO 13485:2016 and ISO 9001:2015. Certification to these standards ensure that our organization has its processes and procedures aligned to provide assured quality services. The management of quality systems starts with the control of raw materials and the selection of suppliers whose products have consistent high-quality standards. All processes are controlled to ensure products and services are amicable to customer requirements. Our goal is to manage, control, review, and continuously improve all business processes. Better process performance, decreasing variations, and maintaining consistent quality of all outputs ensures the highest quality products are being delivered to the market, leading to enhanced customer and employee satisfaction. Focusing on customer satisfaction and success is a core value that influences everything we do. It is this understanding that drives our belief that Westlake Plastics’ quality mission underpins the building of strong customer relationships. Ongoing communication with customers helps us close gaps between customer expectations and our products. Our commitment to total quality is the foundation to the ongoing development of all Westlake Plastics’ personnel. We continually seek better ways to deliver training and drive awareness with all employees to maintain and improve quality standards.

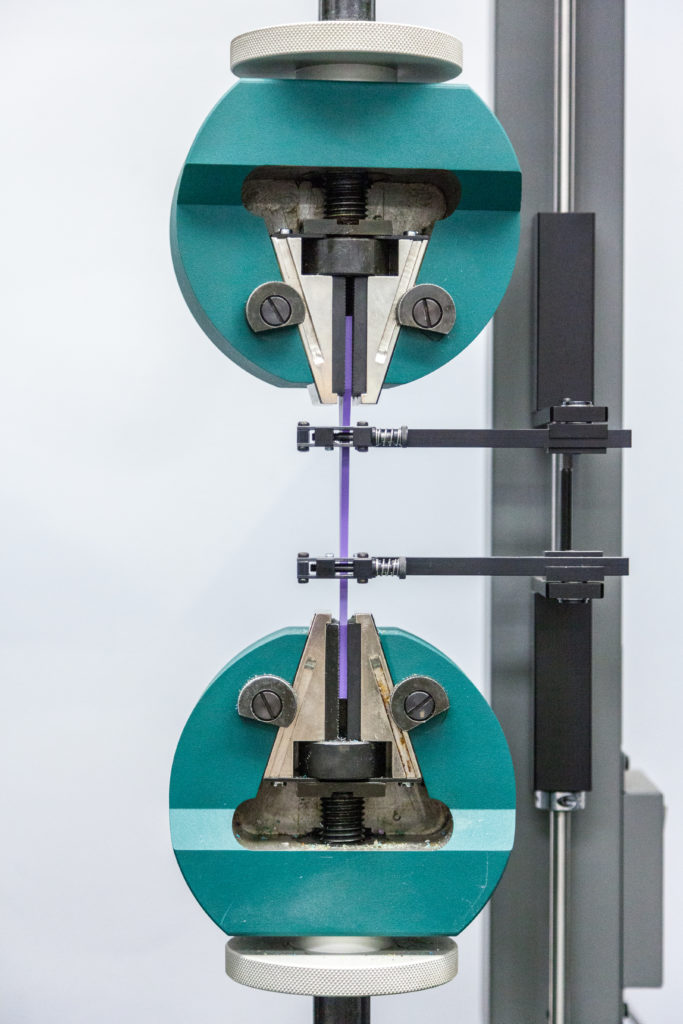

Testing and Characterizations

Westlake has the resources and the expertise to perform tests on both the raw material and the manufactured product at various stages of processing. We have made and continue to make investments in state-of-the-art testing and measurement capabilities. Coupled with our process monitoring and process controls, this ensures customers are receiving the consistent high-quality products they expect. Testing capabilities include: Melt flow rate (MFR), Differential Scanning Calorimetry (DSC) thermal characterization testing, color monitoring via light and color measurement via spectrophotometer, porosity testing via ultrasonic inspection, density testing, and ASTM or ISO tensile and impact testing using CNC machined specimens utilizing our Instron and Tinius Olsen testing units.

Certifications

As a standard practice, Westlake Plastics provides a Certificate of Manufacturing Conformance (COMC) with all products, regardless of polymer composition. This provides traceability to all manufacturing processes and raw material lot information. Where lot testing is required for attributes that extend beyond our internal release criteria, certification charges apply.