Attributes

Westlake Plastics has been involved in the aerospace & defense industry since the 1980s as the first company to process several of the high-performance materials used today. We continue to facilitate our customers’ success by developing new materials that not only meet the stringent end use requirements but also satisfy regulatory requirements.

Aerospace & Defense Key Properties:

- High strength to weight ratio

- Chemical resistance

- Heat resistance

- Flame retardancy

The Aerospace & Defense Lineup

Arolux® PEEK WM

- Higher heat resistance

- Chemical resistant

- High strength

- High stiffness

1 Colors

Arolux® PEKK

- Highest Heat resistance

- Chemical resistant

- High strength

- High stiffness

1 Colors

Fluorolux™

- Chemical resistance

- Heat resistance

- Flammability resistance

1 Colors

Kynar®

- Heat Resistant

- Biocompatibility

- Flammability Resistance

- Food Contact

3 Colors

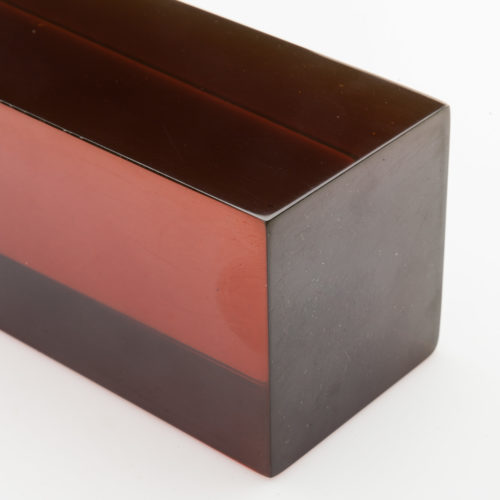

Radel® WM

- Good impact resistance and toughness

- High chemical resistance

- Biocompatible

- High heat resistance

13 Colors

Tempalux®

- High heat resistance

- High strength and stiffness

- Good chemical resistance

- Inherently flame retardant

2 Colors

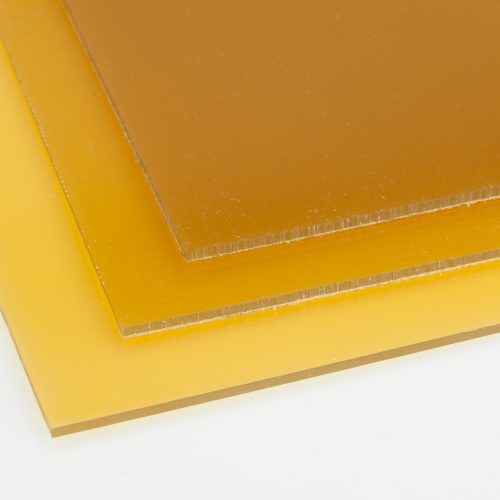

Tempalux® GF20

- High heat resistance

- High strength and increased stiffness

- Good chemical resistance

- Inherently flame retardant

1 Colors

Tempalux® GF30

- High heat resistance

- High strength and increased stiffness

- Good chemical resistance

- Inherently flame retardant

1 Colors

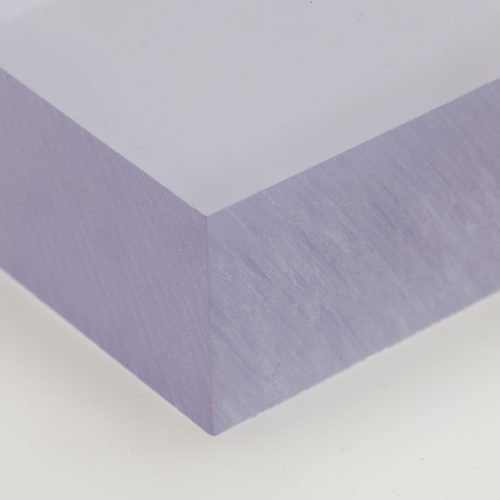

Thermalux® PPSU

- Highest heat resistance

- High strength and stiffness

- Good chemical resistance

- Inherently flame retardant

2 Colors

Zelux® M

- Excellent impact toughness

- Good heat resistance

- Dimensional stability

2 Colors

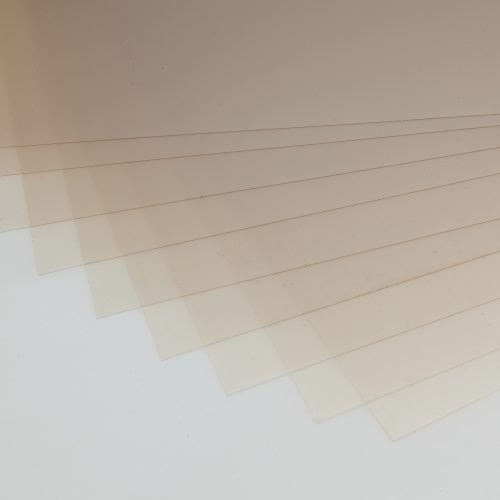

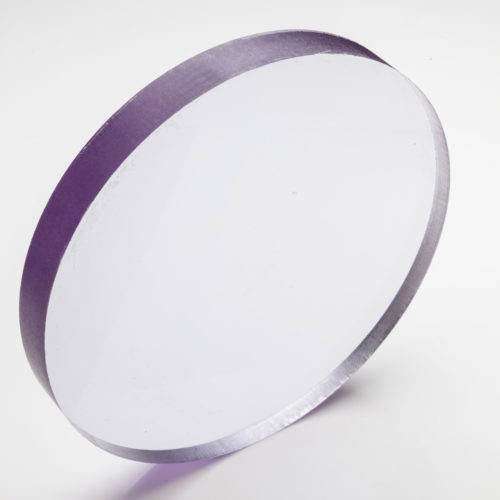

Zelux® W

- Excellent impact toughness

- Good heat resistance

- Dimensional stability

- Optical clarity

1 Colors

“Westlake Plastics is excited to partner with companies like Arkema and Evonik to bring new materials such as Arolux PEKK and Amidelux PA that will help the engineers reduce weight in demanding aerospace applications.”

Jason Ross, Westlake VP of Sales and Marketing