Attributes

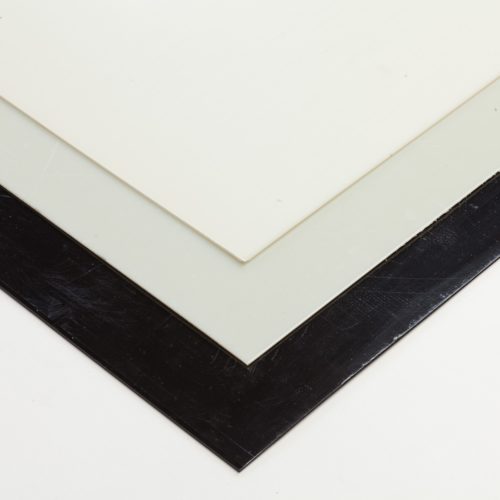

Engineering thermoplastics are a subset of the more commonly utilized commercial materials that have a broad scope of characteristics that include: varying degrees of chemical resistance, dimensional stability, ability to withstand load, and friction. These materials are generally defined for longer-term usage at temperatures from ambient up to 121°C (250°F).

Engineering Key Properties:

- Strength

- Stiffness

- Impact/Toughness

- Moderate Heat Resistance

The Engineering Lineup

Absylux®

- Impact Resistance

- Stiffness

- Dimensional stability

3 Colors

Absylux® CN-P

- Statically conductive

- Stiffness

- Dimensional stability

1 Colors

Absylux® FR

- Flame resistant

- Stiffness

- Dimensional stability

1 Colors

Absylux® SD-A

- Antistatic

- Stiffness

- Dimensional stability

2 Colors

Amidelux™

- Transparency

- Impact resistance

- Chemical resistance

1 Colors

Ardel™

- Transparency

- UV resistance

- Heat resistant

1 Colors

Arolux® PPS

- High Heat resistance

- Chemical resistant

- High strength

- High stiffness

1 Colors

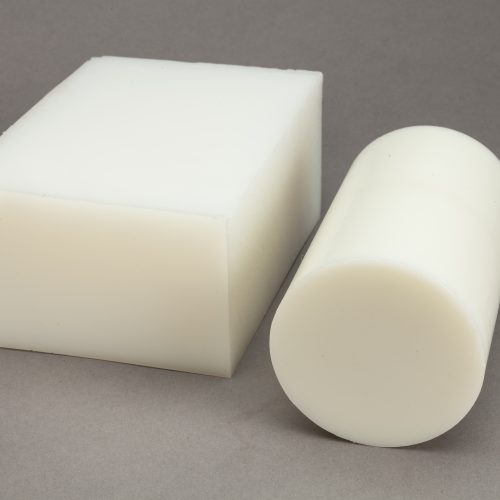

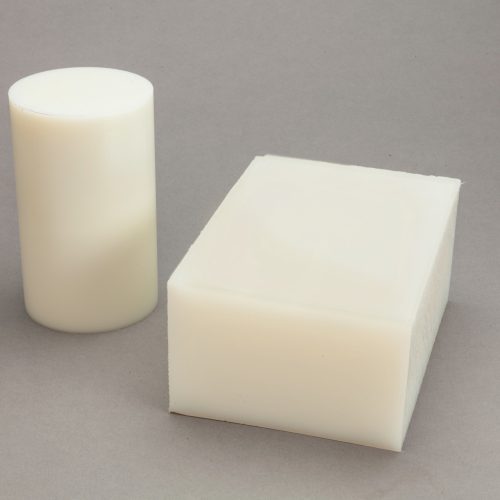

Ethylux®

- Chemical resistance

- Impact resistance

- Low moisture absorption

1 Colors

Norylux™

- Low moisture absorption

- Dimensional stability

- High dielectric strength

1 Colors

Norylux™ GF

- Low moisture absorption

- Dimensional stability

- High strength & stiffness

1 Colors

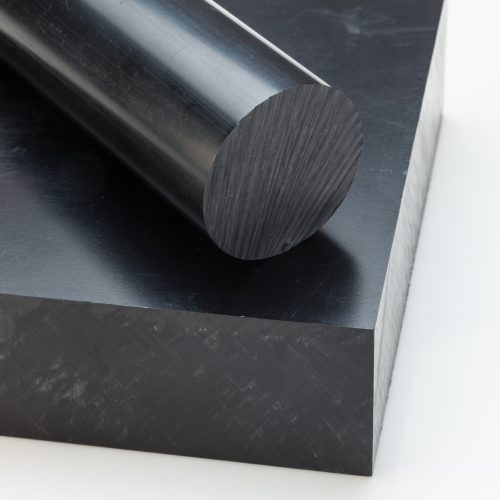

Pomalux®

- Low wear and friction

- Strength

- Chemical resistance

2 Colors

Pomalux® CN-F

- Statically conductive

- High Stiffness

- Strength

- Chemical resistance

1 Colors

Pomalux® CN-P

- Statically conductive

- Stiffness

- Chemical resistance

1 Colors

Pomalux® GF

- Stiffness

- Strength

- Dimensional stability

- Chemical resistance

1 Colors

Pomalux® SD-A

- Antistatic

- Low wear and friction

- Chemical resistance

2 Colors

Pomalux® WR

- Wear Resistance

- Suitable for Food Contact

- Strength

- Stiffness

2 Colors

Pomalux® WRX

- Wear Resistance

- Suitable for Food Contact

- Strength

- Stiffness

2 Colors

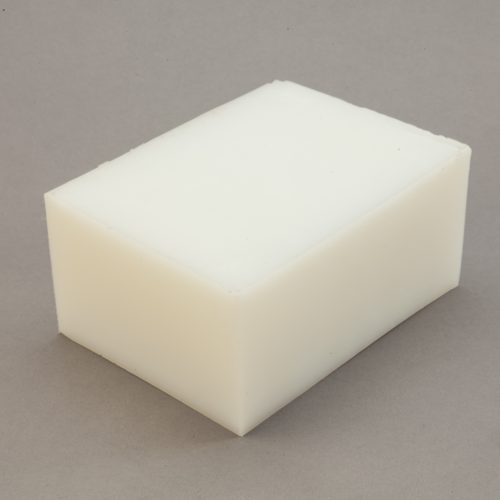

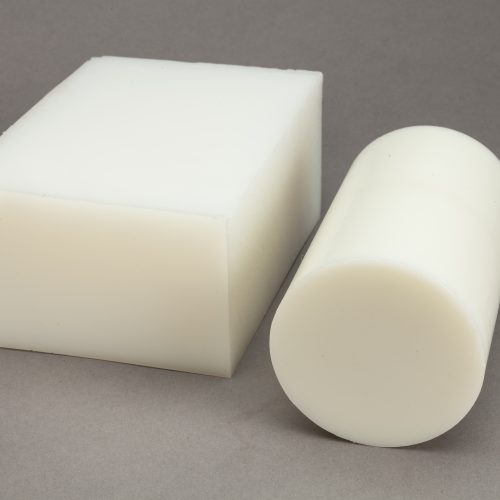

Propylux®

- Chemical Resistance

- Food Contact

- Low Moisture Absorption

2 Colors

Propylux® CN-F

- Statically conductive

- High Stiffness

- Chemical resistance

1 Colors

Propylux® CN-P

- Statically conductive

- Low moisture absorption

- Chemical resistance

1 Colors

Propylux® DS

- Chemical Resistance

- Dimensional Stability

- Toughness/Impact Resistance

1 Colors

Propylux® SD-A

- Antistatic

- Low moisture absorption

- Chemical resistance

2 Colors

Propylux® VF

- Impact resistance

- Chemical resistance

- Low Moisture absorption

1 Colors

Styraclear®

- Transparent

- Food Contact

1 Colors

Styralux™

- Dimensional Stability

- Food Contact

1 Colors

Thermalux® PESU

- High heat resistance

- High strength and stiffness

- Good chemical resistance

1 Colors

Thermalux® PPSU

- Highest heat resistance

- High strength and stiffness

- Good chemical resistance

- Inherently flame retardant

2 Colors

TPX™

- Low density

- Low dielectric constant

- Low water absorption rate, but high gas permeability

1 Colors

Ultra Ethylux®

- Chemical resistance

- Impact resistance

- Low Moisture Absorption

2 Colors

Ultra Ethylux® DS

- Chemical Resistance

- Impact Resistance

- Low Moisture Absorption

- Dimensional Stability

1 Colors

Zelux® CN-P

- Statically conductive

- Good heat resistance

- Dimensional stability

1 Colors

Zelux® M

- Excellent impact toughness

- Good heat resistance

- Dimensional stability

2 Colors

Zelux® M 20% G/F

- Strength and stiffness

- Good heat resistance

- Dimensional stability

1 Colors

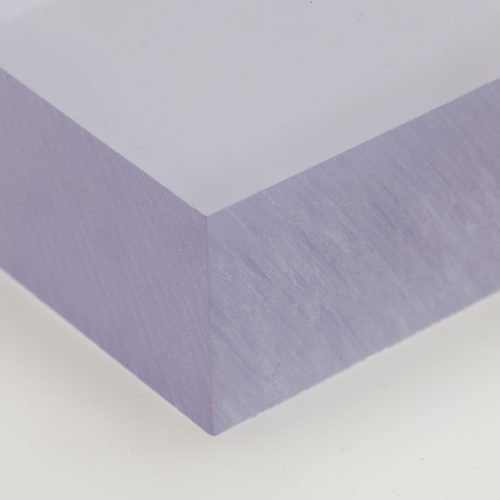

Zelux® SD-P

- Antistatic

- Good heat resistance

- Dimensional stability

1 Colors

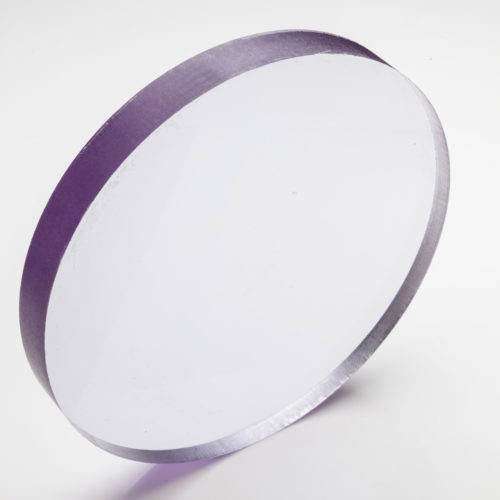

Zelux® W

- Excellent impact toughness

- Good heat resistance

- Dimensional stability

- Optical clarity

1 Colors

Dimensionally stable sheet to save processing time "When you machine it, there is no need to have a secondary process to anneal it and remove the stress”

Kipp Walden, Curbell Sales Manager