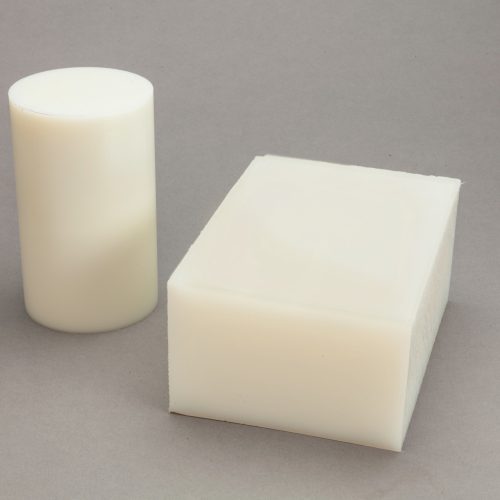

Propylux™ Family

Propylux HS®

Propylux® HS (Heat Stabilized polypropylene) extruded shapes are made from FDA, USP VI compliant polypropylene resin. Its broad chemical resistance, low moisture absorption, hydrolysis resistance, and toughness make it ideal for medical and life science applications. It is put through a unique heat stabilization process that stress-relieves the material, improves the dimensional stability, and enables the material to be repeatedly steam sterilized without loss of mechanical properties, aesthetics or dimensional stability. Suitable sterilization methods include steam autoclaving, EtO gas, and cold sterilization. Propylux® HS is fully lot traceable.

Industry

Attributes

Typical Properties

| Property | Test Standard | English Units | Metric Units |

| Mechanical | |||

| Flexural Modulus | D790 | 313 kpsi | 2,158.00 MPa |

| Flexural Strength - 5% | D790 | 9.2 kpsi | 64.00 MPa |

| Izod Impact Resistance - Notched | D256 | 0.90 ft-lb/in | 48.00 J/m |

| Tensile Elongation @ Break | D638 | 20-60% | 20-60% |

| Tensile Elongation @ Yield | D638 | 4.60 % | 4.60 % |

| Tensile Strength @ Break | D638 | 3.9 kpsi | 27.00 MPa |

| Tensile Strength @ Yield | D638 | 5 kpsi | 35.00 MPa |

| Thermal | |||

| HDT @ 66 psi | D648 | 302 °F | 150 °C |

| HDT @ 264 psi | D648 | 160 °F | 71 °C |

| Physical | |||

| Specific Gravity | D792 | 0.90 | 0.90 |

| *Data above is based on testing of machined test specimens made from extruded bar stock | |||

Rod Sizing

Sheet Sizing

Slab Sizing

Documentation

No documents found.

Similar Products

Non-standard (Made to Order)

Standard Stock

Propylux™ VF

polypropylene

- Impact resistance

- Chemical resistance

- Low Moisture absorption

1 Colors

Standard Stock

Propylux™ CN-P

polypropylene

- Statically conductive

- Low moisture absorption

- Chemical resistance

1 Colors

Standard Stock

Propylux™ CN-F

polypropylene

- Statically conductive

- High Stiffness

- Chemical resistance

1 Colors

Standard Stock

Propylux™ SD-A

polypropylene

- Antistatic

- Low moisture absorption

- Chemical resistance

2 Colors