Zelux® Family

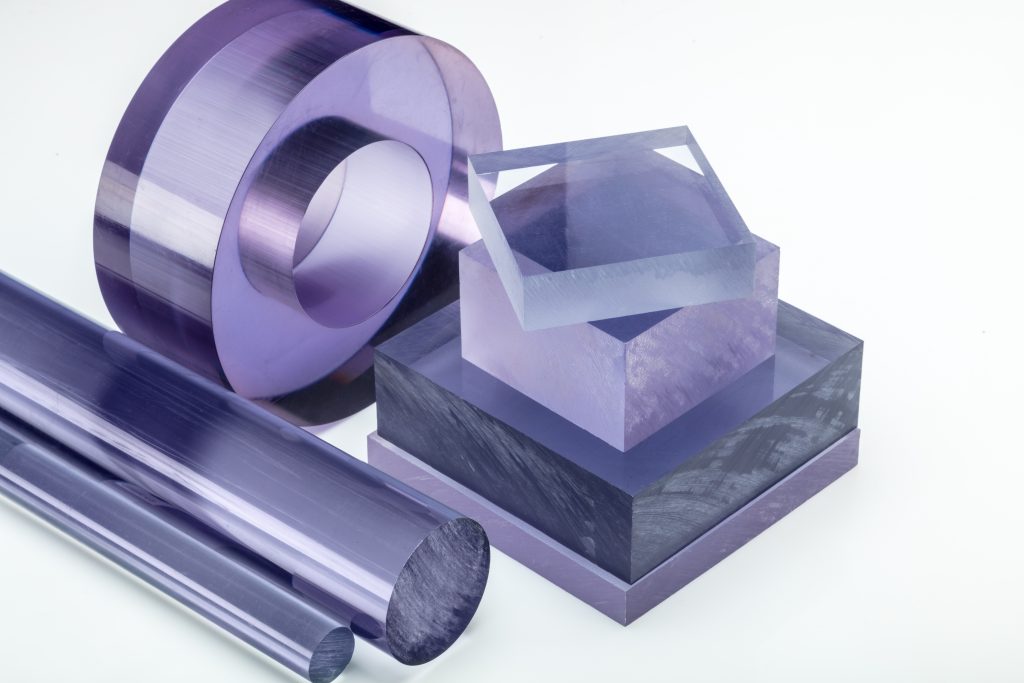

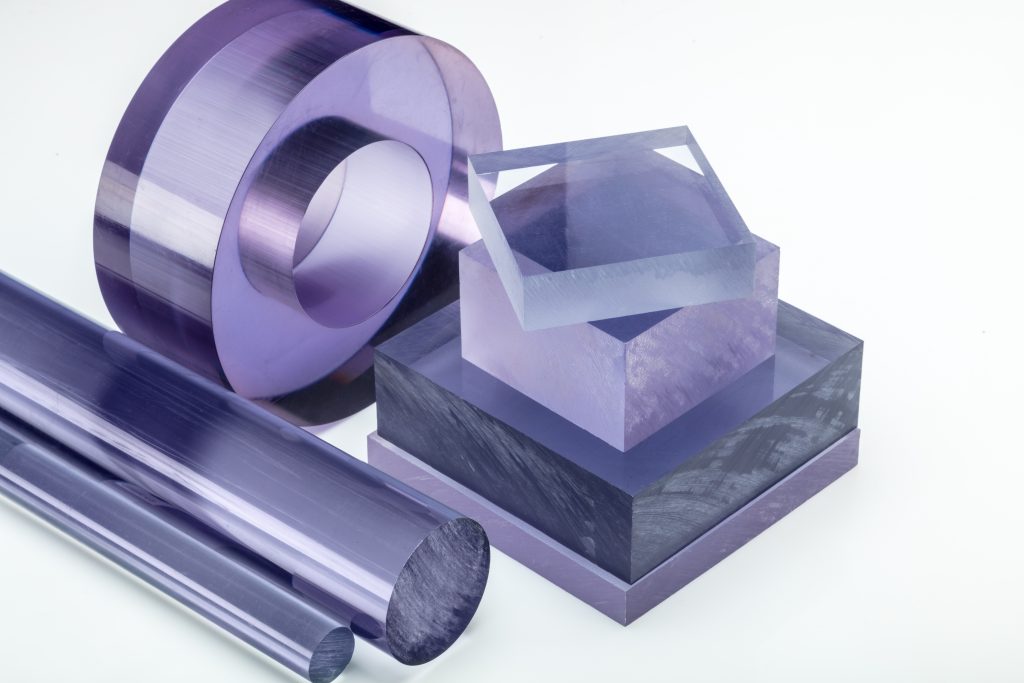

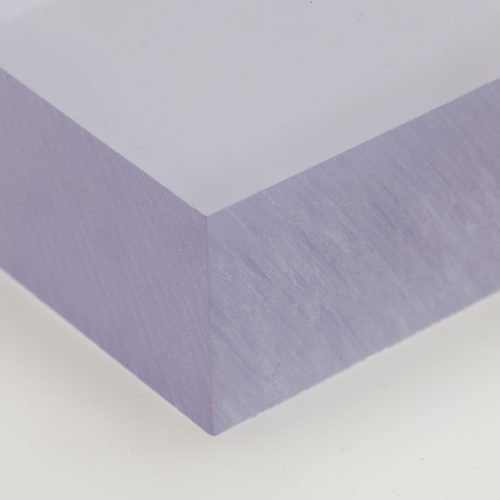

Zelux® M WM

Zelux® M WM is a range of extruded polycarbonate preform products designed for medical device and life science applications that are intended to be sterilized via ethylene oxide (EO). Parts made from Zelux M WM exhibit excellent impact resistance and good strength and stiffness up to 250°F. Resin used to produce Zelux M WM meets the requirements of USP VI and ISO 10993 biocompatibility standards. Extruded product is fully lot traceable.

Industry

Attributes

Colors Available

Typical Properties

| Property | ASTM Test Method | English Units | Metric Units |

| Mechanical | |||

| Flexural Modulus | D790 | 339 kpsi | 2340 MPa |

| Flexural Strength - Yield | D790 | 14 kpsi | 97 MPa |

| Izod Impact Resistance - Notched | D256 | 16.99 ft-lb/in | 907 J/m |

| Tensile Elongation @ Break | D638 | 135% | 135% |

| Tensile Elongation @ Yield | D638 | 7% | 7% |

| Tensile Modulus | D638 | 335 kpsi | 2310 MPa |

| Tensile Strength @ Break | D638 | 9.8 kpsi | 68 MPa |

| Tensile Strength @ Yield | D638 | 8.9 kpsi | 62 MPa |

| Thermal | |||

| HDT @ 264 psi | D648 | 255 °F | 124 °C |

| HDT @ 66 psi | D648 | 275 °F | 135 °C |

| Physical | |||

| Moisture Absorption (24h, 23C) | D570 | 0.15% | 0.15% |

| Specific Gravity | D792 | 1.20 | 1.20 |

| *Data above is based on testing of injection molded test specimens | |||

Rod Sizing

Sheet Sizing

Film Sizing

Slab Sizing

Extruded Sheet Sizing

Outlined below are the common gauges we produce.

Other gauges available, please call your Westlake Plastics Representative for details.

Roll Width: 26 in. +0.25 in/-0.00 in

Finish: Polish/Matte (P/M)

Gauge Tolerance: +/-10%

Standard Roll weight: 50 lbs.

Standard Core: 6" corrugated/fiber

Documentation

No documents found.

Similar Products

Non-standard (Made to Order)

Standard Stock

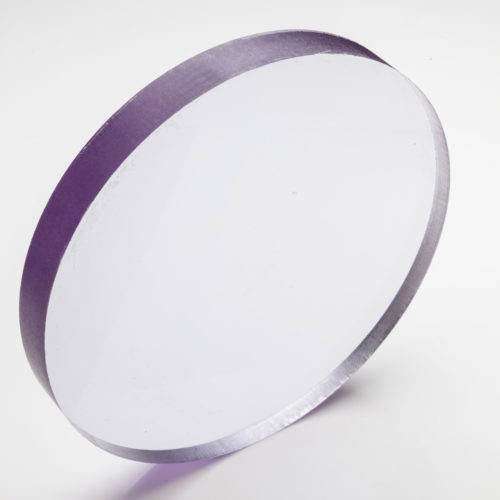

Zelux® M

polycarbonate

- Excellent impact toughness

- Good heat resistance

- Dimensional stability

2 Colors

Standard Stock

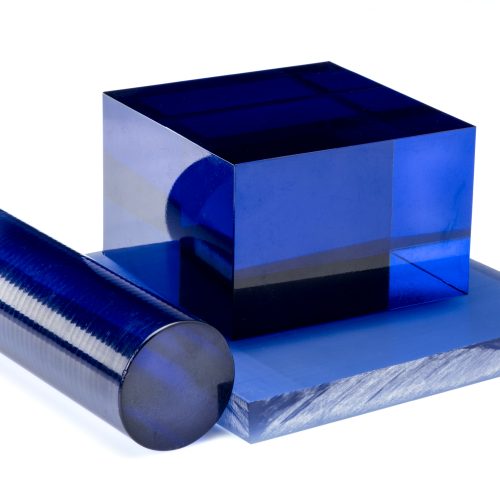

Zelux® W

polycarbonate

- Excellent impact toughness

- Good heat resistance

- Dimensional stability

- Optical clarity

1 Colors

Non-standard (Made to Order)

Standard Stock

Zelux® GS

polycarbonate

- Excellent impact, toughness

- Good heat resistance

- Dimensional stability

- Biocompatible

1 Colors

Standard Stock

Zelux® CN-P

polycarbonate

- Statically conductive

- Good heat resistance

- Dimensional stability

1 Colors