Westlake Plastics Company (Lenni, PA) and Environmental Composites, Inc. (Utica, NY) today announced the launch of Aerolite Carbon, a joint product venture resulting in a new advanced composite material technology compatible with standard thermoforming equipment (vacuum forming / pressure forming).

• New innovative material technology allows lighter, more durable carbon fiber drone components at an affordable price.

• Ideal material option for aerodynamic shrouds and other components to reduce weight and ultimately increase flight time.

• Fast and affordable manufacturing using standard thermoforming equipment allows adoption in consumer and specialty drones at even the most competitive price points.

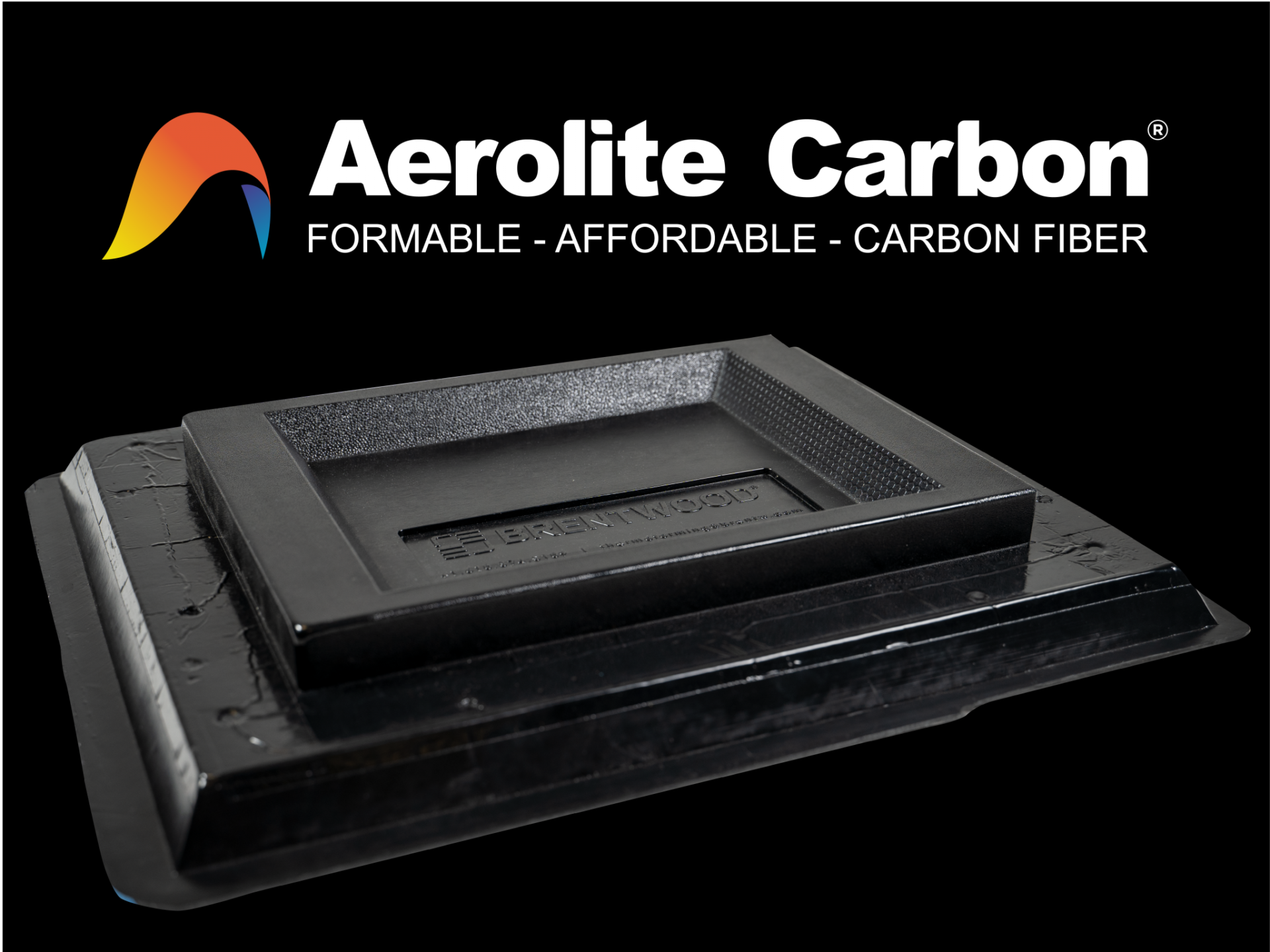

The product supports large volume applications with standard 4’ x 8’ sheet size, capable of being processed in under 2 minutes. Aerolite Carbon was developed to deliver better economy and throughput, while utilizing an existing global supply chain for part conversion. Complex geometry formation and as-molded cosmetic finishes are achieved in a single-step forming process through a proprietary carbon fiber reinforced sheet design.

Aerolite Carbon is an advanced carbon fiber textile impregnated with a proprietary thermoplastic alloy resin. The unique material chemistry and construction allow Aerolite Carbon to stretch uniformly when heated to form deep draws and sharp angles on simple one-sided tooling. Due to the lower cost and high throughput, Aerolite Carbon targets both consumer and industrial applications seeking lightweight performance products at minimal cost. Color matching, as-molded textures, class A surfaces and custom graphics are all possible with Aerolite Carbon.

Aerolite Carbon was developed jointly by Westlake Plastics (Lenni, PA), a global leader in advanced thermoplastic extrusion, and Environmental Composites, an industry leader in advanced textiles. Using the combined resources of both companies, they have invested in equipment and process technology to achieve a hybrid material, which combines advanced composites performance with thermoformable plastics economics. The result is Aerolite Carbon which allows designers to economically achieve carbon fiber performance in their applications through lower manufacturing costs.

Read the full press release in UAS Magazine.